Die cut box is a popular packaging solution that has revolutionized how products are shipped and stored. These boxes are made using a process known as die-cutting, which involves cutting a sheet of cardboard or corrugated fiberboard into a specific shape or design. The die-cutting process can be used to create various box styles and sizes, making it a versatile packaging option for businesses across different industries.

In this article, we’ll explore the benefits of using die-cut boxes, how they’re made, the different types of die-cut boxes, and their applications in various industries.

Benefits of Die-Cut Boxes :

Customization :

It can be customized to fit the specific dimensions of a product, providing a secure fit that prevents damage during transit.

Branding :

Die cut box can be printed with a company’s logo, message, or other branding elements, helping to increase brand visibility and recognition. You can also use double layer cardboard boxes for packaging.

Cost-effective :

Die-cut boxes are cost-effective as they use less material than traditional boxes, reducing the overall packaging costs.

Environmentally friendly :

Die-cut boxes are made from sustainable materials like cardboard and corrugated fiberboard, which are biodegradable and recyclable.

How are Die-Cut Boxes Made?

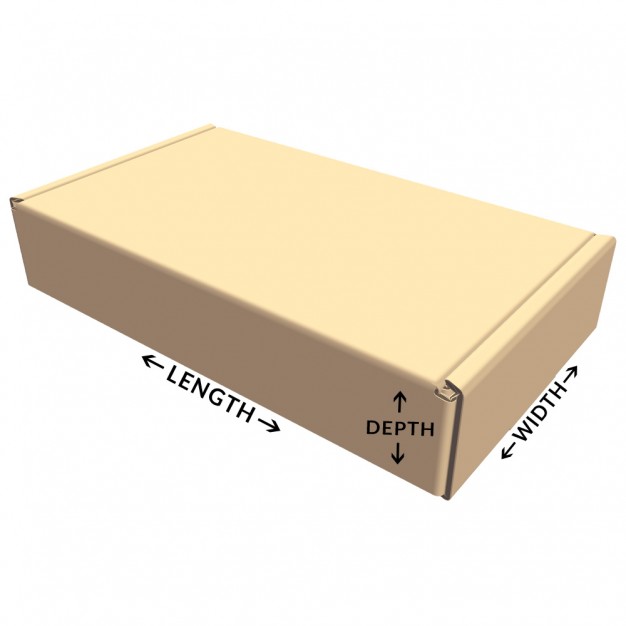

Die cut box are made using a process called die-cutting. The process involves creating a custom die or cutting tool to cut a sheet of cardboard or corrugated fiberboard into a specific shape or design. The die is then used to cut out the box shape from the sheet of material. The excess material is removed, and the box is folded and glued to form the final product.

The die-cutting process can be done manually or using a machine. In manual die-cutting, the die is placed on the sheet of material, and pressure is applied to cut out the shape. In machine die-cutting, the die is mounted on a press, and the sheet of material is fed through the machine, where the die cuts out the shape automatically.

How are Die-Cut Boxes Are Different From Other Traditionally Packaging

Die-cut boxes are a popular choice for Custom Design Mailer Boxes, and for good reason. These boxes are different from traditional packaging boxes in that they are precisely cut to fit the exact dimensions of the product being shipped, which helps to ensure that the contents are secure and protected during transit. Die-cut boxes are also highly customizable, allowing businesses to create unique packaging solutions that showcase their brand and enhance the customer experience. With their sleek design and superior functionality, die-cut boxes are an excellent choice for businesses looking to elevate their packaging game and make a lasting impression on their customers.

Different Types of Die Cut Box

Folding Cartons:

Folding cartons are die-cut boxes for retail packaging, such as cosmetics, pharmaceuticals, and food products. They are made from a single sheet of cardboard and are folded into a box shape.

Corrugated Boxes:

Corrugated boxes are made from corrugated fiberboard and are used for shipping and storage. They are strong, durable, and provide excellent product protection during transit.

Retail Boxes:

Retail boxes are boxes that are used for display and merchandising purposes. They can be customized to fit a specific product and can be printed with a company’s branding elements.

Mailer Boxes:

Mailer boxes are used for shipping small to medium-sized products. They are self-sealing, and their design provides excellent protection during transit.

Applications of Die-Cut Boxes:

Die-cut boxes are used across various industries, including:

Retail: Die cut box are used for retail packaging’s, such as cosmetics, pharmaceuticals, and food products.

E-commerce: Die-cut boxes are used for shipping products sold online. They are durable and provide excellent protection during transit.

Manufacturing: Cutting boxes are used for storing and shipping raw materials and finished products.

Advertising: It can be printed with a company’s branding elements, making them an effective advertising tool.

Conclusion

These boxes are a versatile packaging solution that offers numerous benefits, including customization, branding, cost-effectiveness, and eco-friendliness. The die-cutting process allows for the creation of various box styles and sizes, making them suitable for different applications across various industries. Whether in retail, e-commerce, manufacturing, or advertising, die-cut boxes can provide a reliable and efficient packaging solution for your products.

With their ability to be customized and printed with branding elements, die-cut boxes can also help to increase brand visibility and recognition.

Read this article also : 3 ply carton box

As more businesses focus on sustainability, die-cut boxes have become increasingly popular due to their eco-friendly nature. Made from sustainable materials like cardboard and corrugated fiberboard, they are biodegradable and recyclable, making them a responsible packaging choice for businesses.

In conclusion, die-cut boxes offer a range of benefits that make them an attractive packaging solution for businesses of all sizes and industries. Their ability to be customized, cost-effective, and environmentally friendly make them an excellent choice for businesses looking to optimize their packaging processes while promoting their brand and reducing their environmental impact.